Coated timing belts are a type of synchronous belt used in various applications, particularly in industrial machinery and automotive systems. These belts are designed with a special coating on the tooth side, which enhances their performance and provides specific advantages for certain applications.

coated timing belts offer enhanced traction, reduced noise, and vibration, increased durability, and resistance to chemicals and temperature variations, making them a valuable choice for specific industrial and automotive applications.

Coated timing belts are a type of synchronous belt used in various applications, particularly in industrial machinery and automotive systems. These belts are designed with a special coating on the tooth side, which enhances their performance and provides specific advantages for certain applications.

coated timing belts offer enhanced traction, reduced noise, and vibration, increased durability, and resistance to chemicals and temperature variations, making them a valuable choice for specific industrial and automotive applications.

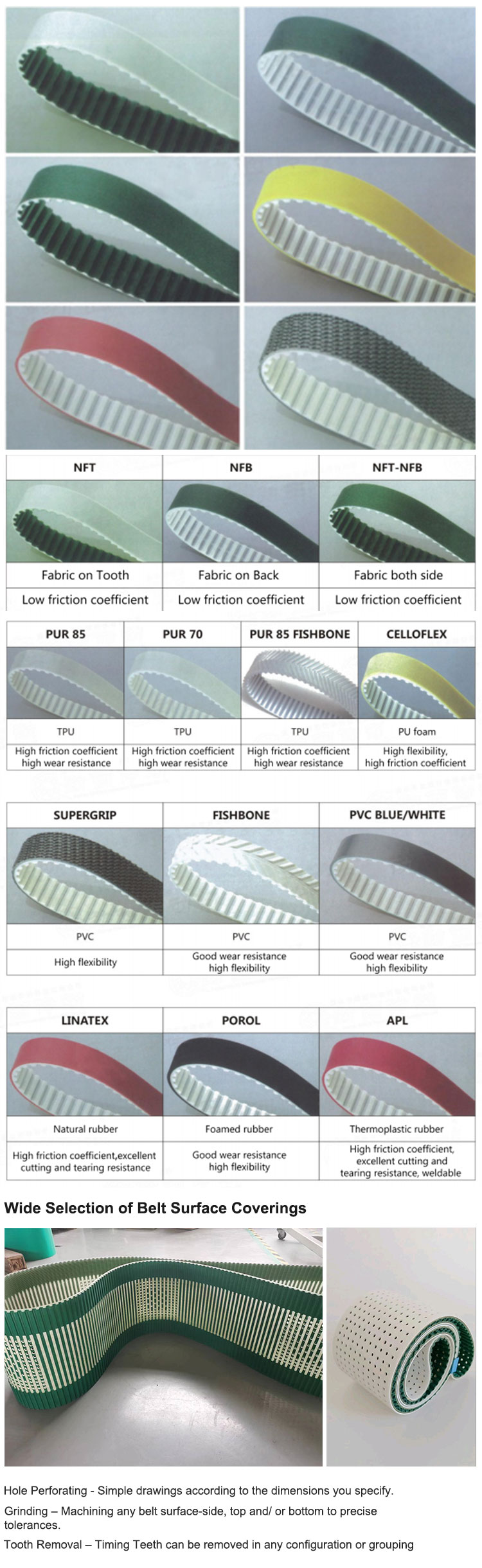

| Materials | Fabric on Tooth | Low friction coefficient |

| Fabric on Back | Low friction coefficient | |

| Fabric both side | Low friction coefficient | |

| TPU | High friction coefficient,high wear resistance | |

| PU foam / Sponge | High flexibility,high friction coefficient | |

| PVC(Supergrip,fishbone,etc.) | Good wear resistance,high flexibility | |

| Natrial Rubber / Linatex | High friction coefficient,excellent cutting and tearing resistance | |

| Foamed rubbe / Porol | Good wear resistance,high flexibility | |

| Thermoplastic rubber / APL | High friction coefficient, excellent cutting and tearing resistance, weldable | |

| Silicone | High-temperature resistance,anti-adhesive properties | |

| Endless Belts | Seamless | |

| Jointed | ||

| TRADEMARK | HOLO | |

| ORIGIN | Wenzhou Zhejiang China | |

| FUNCTION | Transpor | |

| MATERIAL | PU,Steel cord/Kevlar cord | |

| CUSTOMIZE | Available | |

| MODEL NUMBER | XL,L,H,XH,XXH,T5,T10,T20,AT5,AT10,AT20,TG5,TG10,TG20, ATG5,ATG10,ATG20,HTD3M,HTD5M,HTD8M,HTD14M,HTD20M,S3M,S5M,S8M,S14M,RPP5,RPP8,RPP14 | |

| TYPE | Timing belt with covers | |

| COLOR | White,Customize | |

| WIDTH | Customize | |

| LENGTH | Customize | |

| PACKAGING | Carton | |

| DEILVERY TIME | 3-7 Working Days | |

| Endless Belts | Seamless,Jointed | |

| Materials | Fabric on Tooth | Low friction coefficient |

| Fabric on Back | Low friction coefficient | |

| Fabric both side | Low friction coefficient | |

| TPU | High friction coefficient,high wear resistance | |

| PU foam / Sponge | High flexibility,high friction coefficient | |

| PVC(Supergrip,fishbone,etc.) | Good wear resistance,high flexibility | |

| Natrial Rubber / Linatex | High friction coefficient,excellent cutting and tearing resistance | |

| Foamed rubbe / Porol | Good wear resistance,high flexibility | |

| Thermoplastic rubber / APL | High friction coefficient, excellent cutting and tearing resistance, weldable | |

| Silicone | High-temperature resistance,anti-adhesive properties | |

| Endless Belts | Seamless | |

| Jointed | ||

| TRADEMARK | HOLO | |

| ORIGIN | Wenzhou Zhejiang China | |

| FUNCTION | Transpor | |

| MATERIAL | PU,Steel cord/Kevlar cord | |

| CUSTOMIZE | Available | |

| MODEL NUMBER | XL,L,H,XH,XXH,T5,T10,T20,AT5,AT10,AT20,TG5,TG10,TG20, ATG5,ATG10,ATG20,HTD3M,HTD5M,HTD8M,HTD14M,HTD20M,S3M,S5M,S8M,S14M,RPP5,RPP8,RPP14 | |

| TYPE | Timing belt with covers | |

| COLOR | White,Customize | |

| WIDTH | Customize | |

| LENGTH | Customize | |

| PACKAGING | Carton | |

| DEILVERY TIME | 3-7 Working Days | |

| Endless Belts | Seamless,Jointed | |

1、3D Printing: Coated timing belts are used in 3D printers to precisely control the movement of the print head and build platform, ensuring accurate layer deposition.

2、Packaging Machinery: These belts find application in packaging equipment to synchronize the movement of conveyors, facilitating smooth and reliable packaging processes.

3、Textile Industry: Coated timing belts are used in textile machinery for precise control of fabric winding, weaving, and printing processes.

4、Robotics: They are employed in robotics to synchronize the movements of robotic arms and actuators, enabling precise and coordinated actions.

5、Automotive Engines: Coated timing belts are used in engines to control the timing of valves and ensure efficient engine performance.

6、CNC Machines: They find use in CNC machines to drive the spindle and coordinate the movement of the cutting tools, ensuring accuracy in machining processes.

7、Medical Equipment: Coated timing belts are used in medical devices like MRI machines for precise motion control and positioning.

8、Food Processing: These belts are employed in food processing machinery to control the movement of conveyor belts and processing equipment.

9、Printers and Plotters: Coated timing belts are used in printers and plotters for precise paper feeding and print head movement.

10、Automated Assembly Lines: They find application in assembly lines to synchronize the movement of various components, enhancing production efficiency.

1、3D Printing: Coated timing belts are used in 3D printers to precisely control the movement of the print head and build platform, ensuring accurate layer deposition.

2、Packaging Machinery: These belts find application in packaging equipment to synchronize the movement of conveyors, facilitating smooth and reliable packaging processes.

3、Textile Industry: Coated timing belts are used in textile machinery for precise control of fabric winding, weaving, and printing processes.

4、Robotics: They are employed in robotics to synchronize the movements of robotic arms and actuators, enabling precise and coordinated actions.

5、Automotive Engines: Coated timing belts are used in engines to control the timing of valves and ensure efficient engine performance.

6、CNC Machines: They find use in CNC machines to drive the spindle and coordinate the movement of the cutting tools, ensuring accuracy in machining processes.

7、Medical Equipment: Coated timing belts are used in medical devices like MRI machines for precise motion control and positioning.

8、Food Processing: These belts are employed in food processing machinery to control the movement of conveyor belts and processing equipment.

9、Printers and Plotters: Coated timing belts are used in printers and plotters for precise paper feeding and print head movement.

10、Automated Assembly Lines: They find application in assembly lines to synchronize the movement of various components, enhancing production efficiency.

Question: How do coated timing belts handle high temperatures and extreme conditions?

Answer: Our coated timing belts are engineered with heat-resistant materials, ensuring excellent performance in high-temperature environments. They can withstand extreme conditions without compromising their integrity.

Question: Are coated timing belts susceptible to wear and abrasion?

Answer: While all belts experience some level of wear, our coated timing belts are designed with durable and abrasion-resistant coatings. This enhances their lifespan and minimizes the need for frequent replacements.

Question: Can the coatings on timing belts resist chemicals and oils?

Answer: Yes, the coatings on our timing belts are formulated to resist a wide range of chemicals and oils, making them suitable for various industrial applications where exposure to such substances is common.

Question: Do coated timing belts ensure precise positioning and accurate motion control?

Answer: Absolutely! Our coated timing belts offer excellent traction and grip, enabling precise positioning and accurate motion control in machinery and automation systems.

Question: How do coated timing belts handle static electricity buildup?

Answer: We incorporate anti-static properties into our coated timing belts, reducing static electricity buildup and the associated risks in applications where it's a concern.

Question: Are there any concerns with noise and vibration during belt operation?

Answer: Our coated timing belts are designed to run smoothly, reducing noise and vibration during operation. This promotes a quieter and more comfortable working environment.

Question: Can the coatings on timing belts resist moisture and humidity?

Answer: Yes, our coated timing belts are formulated to resist moisture and humidity, ensuring consistent performance and preventing degradation in damp conditions.

Question: Are there specialized coatings available for unique applications?

Answer: We offer a range of specialized coatings tailored to specific applications. Whether you require enhanced grip, increased wear resistance, or compatibility with certain materials, we can provide a coating that meets your needs.

Question: How do coated timing belts address the risk of slipping and misalignment?

Answer: The coatings on our timing belts provide superior grip, minimizing the risk of slipping and misalignment. This results in smoother operation and improved overall efficiency.

Question: What measures are in place to prevent delamination or peeling of the coatings?

Answer: Our coated timing belts undergo rigorous testing to ensure proper adhesion of the coatings to the belt surface. The materials used are carefully selected to prevent delamination or peeling, ensuring long-lasting performance.

Question: How do coated timing belts handle high temperatures and extreme conditions?

Answer: Our coated timing belts are engineered with heat-resistant materials, ensuring excellent performance in high-temperature environments. They can withstand extreme conditions without compromising their integrity.

Question: Are coated timing belts susceptible to wear and abrasion?

Answer: While all belts experience some level of wear, our coated timing belts are designed with durable and abrasion-resistant coatings. This enhances their lifespan and minimizes the need for frequent replacements.

Question: Can the coatings on timing belts resist chemicals and oils?

Answer: Yes, the coatings on our timing belts are formulated to resist a wide range of chemicals and oils, making them suitable for various industrial applications where exposure to such substances is common.

Question: Do coated timing belts ensure precise positioning and accurate motion control?

Answer: Absolutely! Our coated timing belts offer excellent traction and grip, enabling precise positioning and accurate motion control in machinery and automation systems.

Question: How do coated timing belts handle static electricity buildup?

Answer: We incorporate anti-static properties into our coated timing belts, reducing static electricity buildup and the associated risks in applications where it's a concern.

Question: Are there any concerns with noise and vibration during belt operation?

Answer: Our coated timing belts are designed to run smoothly, reducing noise and vibration during operation. This promotes a quieter and more comfortable working environment.

Question: Can the coatings on timing belts resist moisture and humidity?

Answer: Yes, our coated timing belts are formulated to resist moisture and humidity, ensuring consistent performance and preventing degradation in damp conditions.

Question: Are there specialized coatings available for unique applications?

Answer: We offer a range of specialized coatings tailored to specific applications. Whether you require enhanced grip, increased wear resistance, or compatibility with certain materials, we can provide a coating that meets your needs.

Question: How do coated timing belts address the risk of slipping and misalignment?

Answer: The coatings on our timing belts provide superior grip, minimizing the risk of slipping and misalignment. This results in smoother operation and improved overall efficiency.

Question: What measures are in place to prevent delamination or peeling of the coatings?

Answer: Our coated timing belts undergo rigorous testing to ensure proper adhesion of the coatings to the belt surface. The materials used are carefully selected to prevent delamination or peeling, ensuring long-lasting performance.